3D printing

Ideal for the production of prototypes and short series in polyamide

Request your quotation with a CAD file to obtain

the quotation of your pieces

Parts manufactured and shipped in only 5 working days

Production of CUSTOM-MADE, COMPLICATION-FREE parts

What is 3D printing?

3D printing

3D printing, or additive manufacturing, is a production method with which a physical part is manufactured based on a design created with a 3D software.

There are many technologies currently used for 3D printing, but we at Proto&GO! are specialised in printing by MJF (Multi Jet Fusion), the latest technology from HP specially designed for industrial applications.

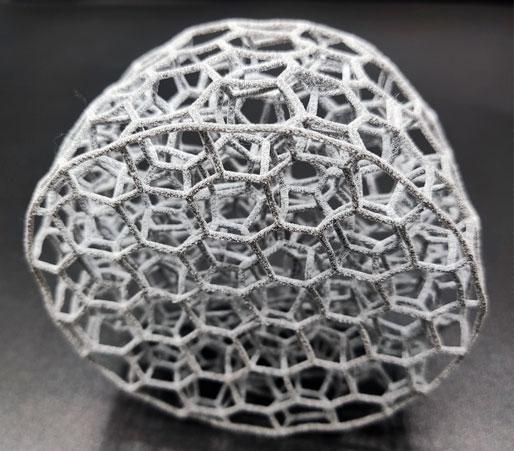

This is the most advanced technology with an industrial orientation for the manufacturing of parts made of polyamide PA12, a rigid, strong and ductile material, and TPA, a robust and flexible material. With this technology, functional technical components can be achieved.

Most advanced Technology

From Prototypes to industrial Series Production

Multijet technology has made the step from additive manufacturing of prototypes to the production of industrial end-use parts. This technology allows the manufacturnig of serial parts in a very short time without the need for high investments in moulds or tools.

The Multijet Fusion Technology

During the printing process, a movable print head applies a thermally conductive melting agent to a powder layer of polyamide with a thickness of a few micrometres. Immediately afterwards, a heat source with infrared light lamps is applied, heating the powder and leading it to melt.

100% Functional Parts

By means of this 3D printing technology, functionally stronger parts can be obtained than with other technologies such as laser sintering, since 100% isotropic parts are obtained, which means that they offer the same resistance in any of the axes, without forgetting the high precision that is achieved.

Materials

PA12

Polyamide PA12 is one of the most practical technical plastics on the market. It is used in all major industries and in many demanding applications. PA12 is mechanically robust, heat-resistant and biocompatible. It also has a very high resolution and precision, which is why it is used not only for prototypes but also for small series production of functional parts.

TPA

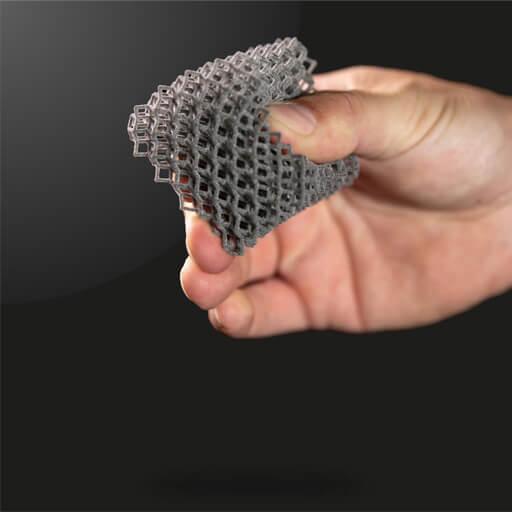

TPU M95A is a flexible material suitable for the production of parts using 3D printing. This thermoplastic polyamide (TPA) is designed for both prototyping and production and due to its excellent durability and mechanical properties is perfect for end-use parts. Parts made from this material offer high wear resistance, rubber-like elasticity (Shore ~ 90A) and high breaking elongation.

Parts with complex geometries and 100% functional

MANUFACTURING PROCESSES

Advantages of 3D printing

Materials

Unlike other additive manufacturing technologies, parts printed with HP MultiJet Fusion are perfectly isotropic, i.e. the strength offered by a printed part is the same in any of its three axes and therefore in any direction of stress.

Speed

Thanks to the print head, the layers take seconds to print. The fusing process, moreover, is integrated into the printing process itself, so there are no additional operations that are not productive. Therefore, the HP MultiJet Fusion are faster machines than any of the FDM or SLS 3D printing technologies.

Resolution

Due to the use of microdroplets, the HP Multi Jet Fusion 3D Printer has a very high resolution, which is unmatched by any other technology. In addition, given the speed of the process, smaller layer heights can be used, further increasing resolution, detail and surface quality.

Material - Rigid or Flexible

In addition to the rigid and resistant PA12, we can now also obtain flexible parts in TPA with a 90A shore. This material is ideal for the manufacture of bellows, seals or any other component that requires a certain elasticity.

Upload your CAD files to our platform, saving management and communication time in other ways.

The 3D file is essential for quoting and must contain only one part.

To indicate the threads present on a part, you must also upload a drawing in .pdf format to the platform.

To use our service it is no longer necessary to invest your time in making all the annotations on the drawings, the 3D file is enough