Description

Metals

Plastics

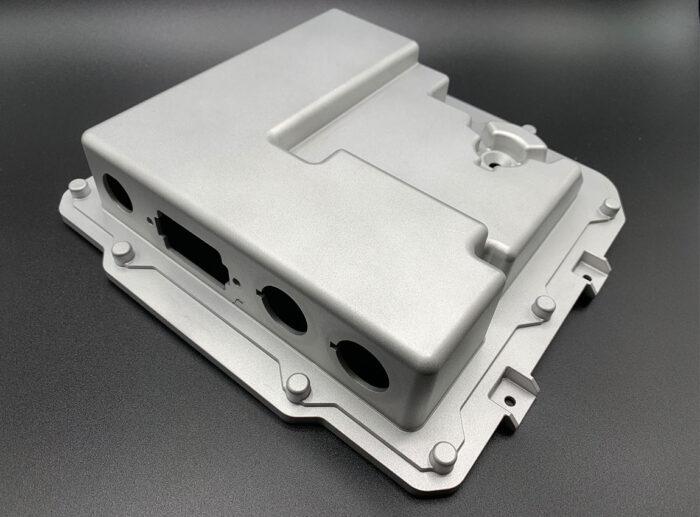

Aluminum is a very versatile metal whose properties make it ideal for the manufacture of prototypes and custom parts by CNC machining. It is a material with an excellent strength-to-weight ratio, good temperature and corrosion resistance, excellent weldability, easy CNC machining and ideal for prototyping. Aluminum machined parts have a low risk of deformation after CNC machining. All its properties make the option of manufacturing machined aluminum parts one of the preferred options for the industry, especially in the automotive, transportation, electronics, aviation, among others.

Technology

CNC machining

Features

- High corrosion resistance

- Good conductor of electricity and heat

- Easy to machine

- Economical material

- Soft, malleable and lightweight material

Applications

- Machinery components

- Automotive parts

- Industrial parts

- Aviation parts

- Kitchen utensils

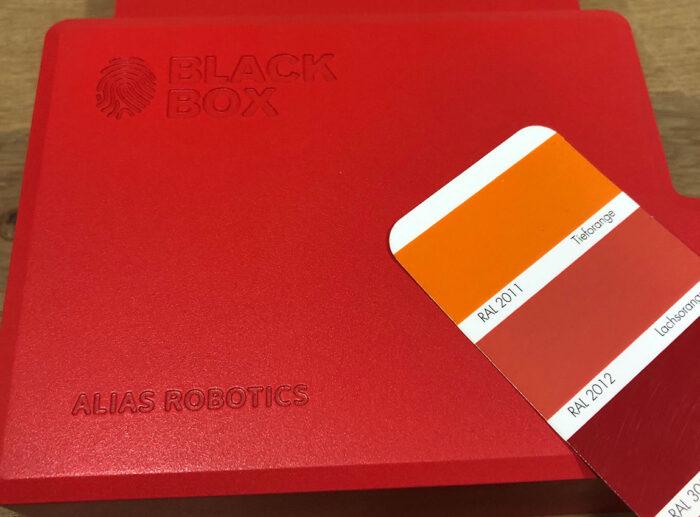

Colours

Properties

- Density: 2700 kg/m³

- Resistance: 690 MPa

- Elastic modulus: 70 GPa

- Melting point: 660 °C

- Boiling point: 2519 °C

- Atomic mass: 26.9815386 (8) u

Alloys

Not specified

The most economical option. We will choose the most suitable alloy according to the geometry and available stock.

5083-H111

Excellent corrosion resistance. Ideal for marine applications.

6061-T651

One of the most widespread aluminum alloys. It is characterized by its hardness and corrosion resistance, as well as its excellent machinability and weldability.

6082-T651

Alloy with slightly higher strength than 6061. Machinery and structural components.

7075-T651

High-strength aluminum alloy originally created for the aerospace industry. High resistance components. High cost.

Datasheet

Finishes options

Unfinished

On unfinished machined aluminum parts, there are visible signs of machining on the surface of the part.

Painting

Surface coat of paint applied on the machined part in powder with the desired color. Available in RAL or Pantone colors.

Anodized

The anodized aluminum part improves the corrosion and aesthetic appearance of the parts. Available colors are: silver, black, red and blue.

Nickel Plating

Nickel coating applied to metals to improve machining strength and aesthetic appearance.

Sandblasting

Sandblasting on aluminum causes a matting of the surface that eliminates machining marks.

Proto&Go! puts at your disposal all its technology to obtain CNC machining in Aluminum.

Thanks to the specific software developed by Proto&Go! you can now easily request your aluminum machining offers through our online form and receive them anywhere in the world by express delivery.

Our CNC machining technology can accommodate both simple aluminum prototypes, common in the industry, as well as 3D prototyping of complex surfaces, thus offering a real alternative to 3D printing or sintering.

Select Aluminum from our more than 100 available materials, both plastic and metallic, upload your 3D files and in less than 24 hours you will receive your online quotation where you will be informed of the expected delivery time.

Do not hesitate to request an offer without obligation and benefit from a technology currently only available to large companies at prices within the reach of any user.

Thank you for trusting Proto&Go! machining services to obtain your prototypes and unique parts in Aluminum.