Description

Metals

Plastics

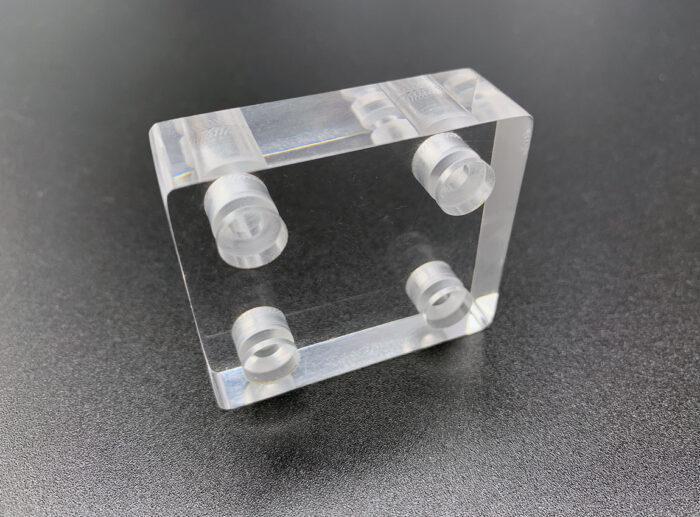

It is an amorphous material, whose most outstanding property is its excellent transparency; hence its main applications are as a substitute for glass.

It is seven times more resistant to breakage than glass at the same thickness, making it more resistant to impact. We recommend adding the clear polish for a better finish.

Technologies

CNC Machining

Features

- Good weather resistance

- Excellent UV resistance

- High chemical resistance

- Good processability

Applications

- Works of art

- Exhibitors

- Protection for machinery

- Glasses manufacturing

- Great aesthetics for prototypes

Colours

Properties

- Temperature: 75℃- 90℃

- Density: 1.18 g/cm3

Datasheet

Finishes options

Painting

Powder coating in the desired colour. RAL or Pantone.

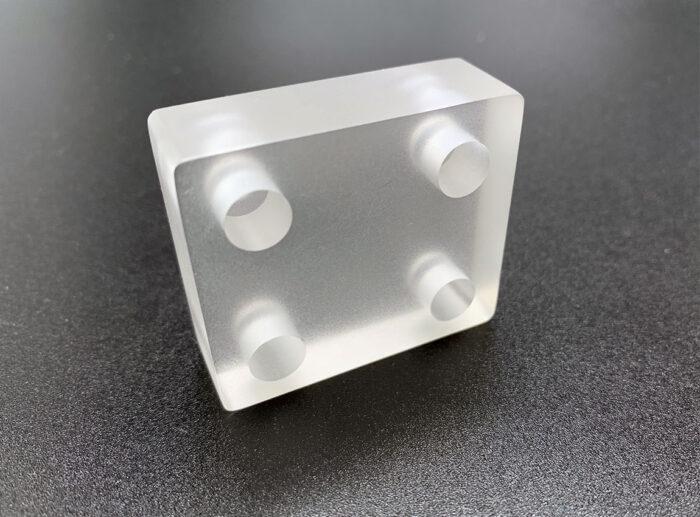

Matt sandblasted

Surface matting that eliminates machining marks.

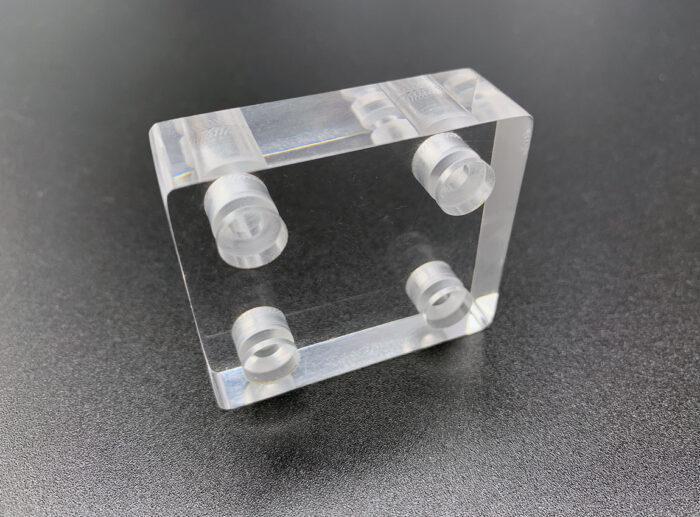

Clear polishing

Finish that achieves a transparent surface. The best choice when transparent parts are required.

Proto&Go! offers you all its technology to obtain CNC machining in PMMA.

Thanks to the specific software developed by Proto&Go! you can now easily request your PMMA machining quotations using our online form and receive them anywhere in the world by express delivery.

Our CNC machining technology accommodates both simple PMMA prototypes, common in industry, as well as 3D prototyping of complex surfaces, thus offering a real alternative to 3D printing or sintering.

Select PMMA from our 100+ available materials, both plastic and metallic, upload your 3D files and within 24 hours you will receive an online quotation with an estimated delivery time.

Do not hesitate to request an offer without obligation and benefit from a technology currently only available to large companies at prices within the reach of any user.

Thank you for trusting Proto&Go! machining services to obtain your prototypes and unique parts in PMMA.