Description

Metals

Plastics

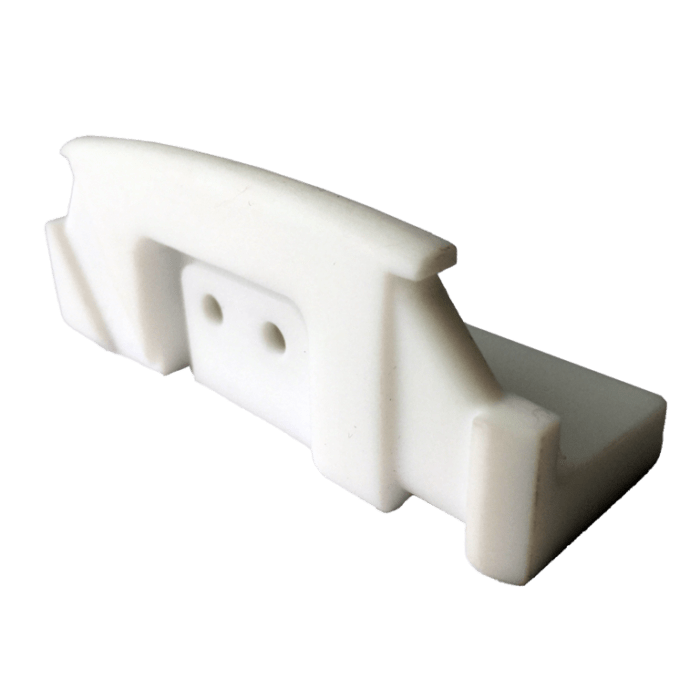

PTFE is a high molecular weight polymer. It is considered a versatile material among the plastic materials on the market, and its usefulness extends to a wide range of products, for applications where other materials cannot be used. It is also characterised as a thermosetting polymer, which maintains a very high viscosity at elevated temperatures.

Technology

CNC Machining

Features

- High resistance to high temperatures

- Good dielectric properties

- High thermal stability

- Good resistance to chemicals

- Good tensile and compressive properties

Applications

- Aerospace coatings

- Prosthesis

- Electronic components

- Structures subject to corrosive environments

Colours

Properties

- Temperature: 260℃

- Hardness: 50 - 60

- Resistance to elongation: 210 - 400%.

- Density: 2.18 g/cm3

Subtype

PTFE - Teflon + GF25%

Datasheet

Proto&Go! offers you all its technology to obtain CNC machining in PTFE – Teflon.

Thanks to the specific software developed by Proto&Go! you can now request your PTFE – Teflon machining offers easily through our online form and receive them anywhere in the world by express delivery.

Our CNC machining technology accommodates both simple PTFE – Teflon prototypes, common in industry, as well as 3D prototyping of complex surfaces, thus offering a real alternative to 3D printing or sintering.

Select PTFE – Teflon from our available materials, both plastic and metallic, upload your 3D files and in less than 24 hours you will receive your online quotation where you will be informed of the expected delivery time.

Do not hesitate to request an offer without obligation and benefit from a technology currently only available to large companies at prices within the reach of any user.

Thank you for trusting in the machining services of Proto&Go! to obtain your prototypes and unique parts in PTFE – Teflon.